We often overlook the humble screw assembly. Sadly the automotive industry has left Australia, but their standards around screw assembly tool selection are worth considering when deciding what type of screwdriver to use.

Think about what happens if a screw joint fails. Will it be annoying, will the product fail or will there be a risk of injury or loss of life?

Programmable Electronic screwdrivers are more in demand these days. Previously their main advantage was their flexibility and traceability, they not only can record the actual torque f every screw, you can fully program every step of the screw assembly as well as instantly change the screwdriving program. However, they are now becoming very much more in demand for Industry 4.0 and more importantly, for product liability reasons.

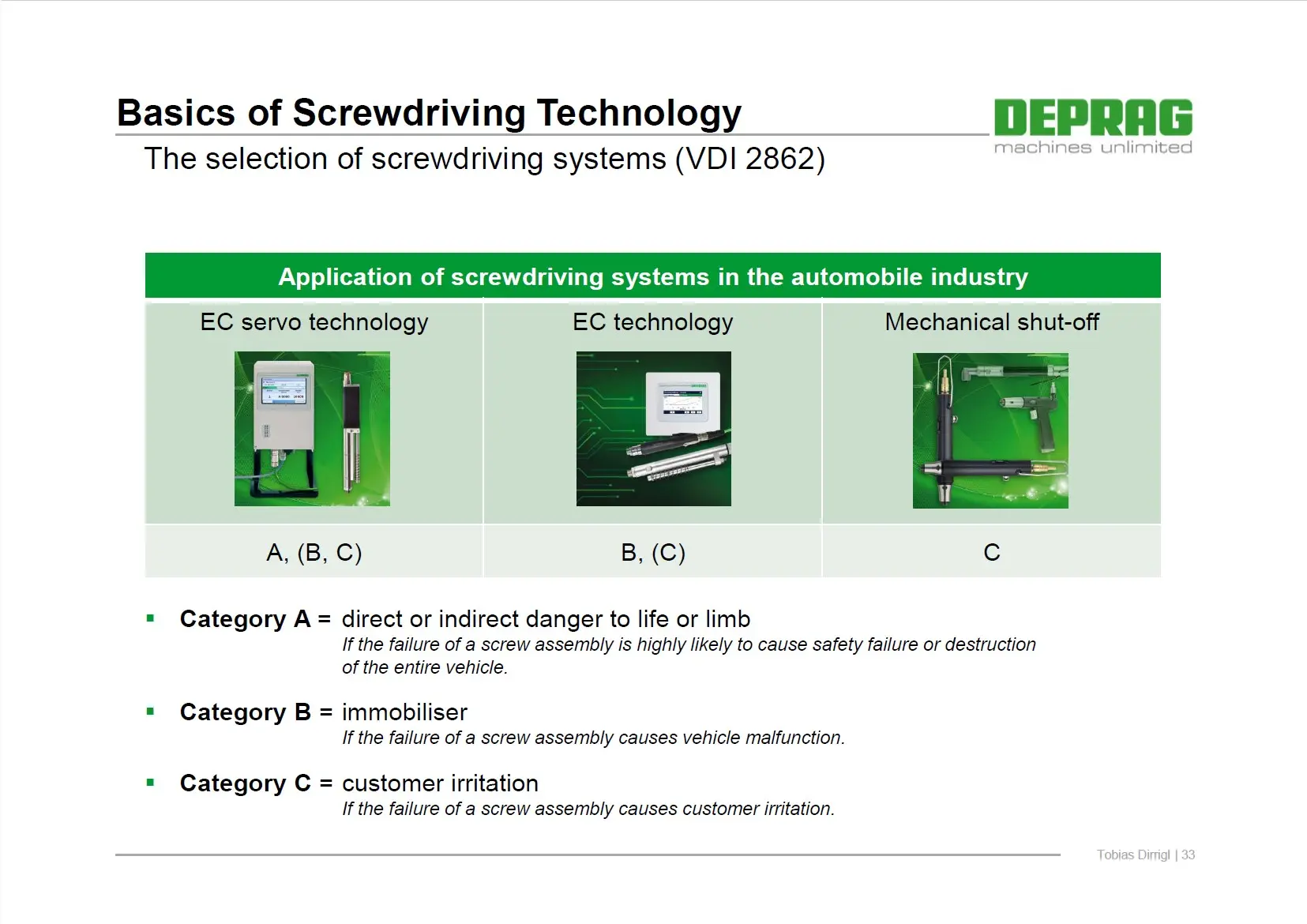

In the Automotive industry there are 3 classifications of screw joints and standards for the screwdriver selection, the standard is VDI 2862. This is driven by tough International product liability laws.

In summary the levels and appropriate DEPRAG screw assembly technologies follow:

Category C = If the failure of a screw assembly causes customer irritation.

DEPRAG's MINIMAT screwdrivers with highly accurate mechanical shut-off clutch. They do not measure or calculate the torque.

Category B = If the failure of a screw assembly causes vehicle malfunction.

DEPRAG's MINIMAT EC or MINIMAT ED range of Electronic screwdrivers which measure or calculate and record torque and/or angle.

Category A = direct or indirect danger to life or limb. If the failure of a screw assembly is highly likely to cause safety failure or destruction of the entire vehicle.

DEPRAG's EC SERVO screwdriver range, with two torque measurement methods (calculate the torque, measure it with a torque transducer and then compare the values).

Please don’t hesitate to contact us if you have any questions.